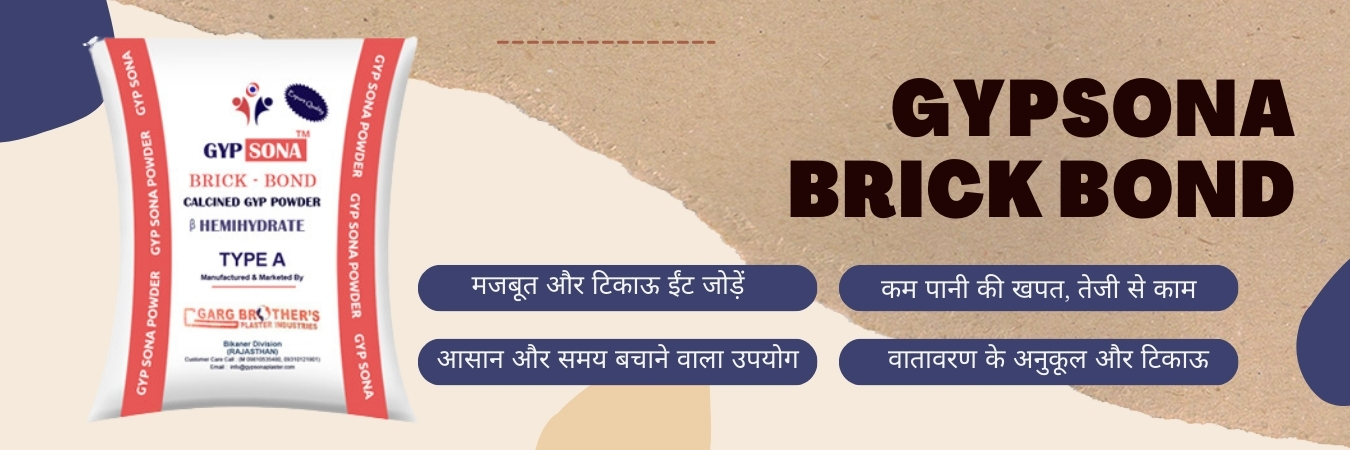

Gypsona is an expert in supplying high-performing gypsum based solutions for the modern construction. Ranging from AAC blocks to fly ash bricks, we have ensured that our Gypsona Brick Bond provides unmatched robustness, longevity, and efficiency to the builders, architects and developers countrywide.

In the construction of sustainable buildings, or improving the ones that already exist, Gypsona is your preferred partner for quality, consistency, and efficiency.

Our products are ingeniously designed Gypsum compounds which are utilized as high-strength binders. With targeted use in:

- ◉ Gypsum for AAC Blocks Manufacturing

- ◉ Gypsum Used in Fly Ash Bricks Manufacturing.

- ◉ Fly Ash Brick Gypsum Powder

With each brick installed, Gypsona guarantees exceptional performance and durability.

Packaging & Specifications

Key Benefits of Using Gypsona

Application in Brick and Block Manufacturing

How to Use – Step-by-Step

-

Mixing

- ◉ 15 Kg of Gypsona Brickbond with 300 Kg of Lime-Fly Ash Mixture

- ◉ Add water gradually and mix thoroughly.

-

Application

- ◉ Feed the mix into your brick/block machine.

-

Curing

- ◉ Allow bricks to cure for 8–10 days for best strength results.

Ideal for AAC Brick Bond Manufacturers and Fly Ash Brick Bond Manufacturers seeking consistent quality and performance.

Sustainable Construction, One Brick at a Time

Choosing Gypsona means you’re not just building walls — you’re building a greener future. Our gypsum products are made with eco-conscious methods, ensuring minimal environmental impact without compromising performance.

Partner with Gypsona Today

Whether you’re a Gypsona Brickbond Manufacturer, an AAC Brick Bond expert, or a startup in Fly Ash Brick Bond manufacturing, we have the right solutions tailored to your goals.

Contact Us Today for Bulk Orders & Sample Testing!

Join the Network of India’s Leading Builders & Innovators.

Gypsona – The Bond That Builds the Future.